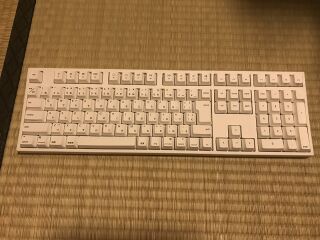

Command Classic/Build 1

The first Command Classic keyboard, built in summer 2020.

Background

At the time I decided to build this keyboard in June 2020, I was cycling between several keyboards on umaru and tiring of their respective tradeoffs. In order to move on from this situation and have a proof of concept, I decided to shortcut plans to build a keyboard that had been shelved for several years.

Design

Two compromises made it possible to start building immediately. The first was handwiring the board. I had wanted to produce a PCB first to avoid the manual labor and do things cleanly from the start, but mastering the knowledge and the tools required to do so is a major time commitment for someone without a background in hardware.

The other was using a sandwich case. Designing a professional-looking enclosure involves 3D CAD software, but a sandwich constructed out of laser-cut sheets of material can be designed easily in two dimensions, without specialized software.

The keymap also features a small compromise with the keymap. I wanted to make something with a bottom row identical to the Macway JIS keyboards, but their 3.5U spacebars do not exist in the parts marketplace, or on any OEM keyboards with Cherry MX-compatible keycap mounts. In order to accomodate the 4.5U space bars used by some Japanese OEM keyboards, I eliminated the 英数 key.

Sourcing Parts: June 2020

Keycaps

Given that I was handwiring and making a case using a common DIY technique, suitable keycaps were the only parts difficult to source. Group buys supporting JIS keymaps were just beginning to appear; at the time, ai03's SimpleJA that ran the previous year (and that I had missed) was the only one. ModernJA was expected to run at an indefinite point in the near future, but no appropriate keycap set was readily available.

I also needed a 4.5U space bar, which led me to look into using an OEM keyboard as a donor. Filco has the spacebar, but their pad-printed ABS caps are not very good relative to other options, only have Windows modifiers are available, and they are unrealistic to mix with other sets due to their idiosyncratic construction and taller profile than common cylindrical caps. Searching for OEM JIS keyboards with dye-sublimated PBT caps that would be pleasant, durable, and mix well with other sets, I landed on Varmilo and chose their "Mac" keyboard for its plain black-on-white design that wouldn't clash with generic caps from other sources.

Mixing keycaps was going to be necessary, because the Varmilo keyboard is really a Windows keymap with Mac-style legends printed on the caps. Fortunately, I was able to assemble a full set of modifiers from multiple kits of a traditional beige and gray IDOBAO set on aliexpress. The Command keys came from a matching set intended for Happy Hacking Keyboard clones.

For good measure, I added some accent purple keys from KPRepublic's "Muted" set. The legends on these keys were thicker and less sharp than the others, though, and they were later replaced with similar, tidier-looking caps from a garden-variety HKGaming set on the Amazon US store. Sets like these were not yet widespread or as cheap as they are now in 2020, or at least I did not notice them at the time.

Plates

After evaluating a few domestic (Japanese) and overseas options for price and ease of use, I decided to order the metal case components from LaserBoost in Barcelona. This consists of two 1.5mm-thick stainless steel plates with the same footprint - a solid one for the bottom, and one to house the keyswitches near the top. I chose to have them sandblasted to improve the appearance and texture of the parts that were to be visible.

Acrylic

My rudimentary design called for acrylic sheets stacked between the steel plates to create a hollow interior in typical sandwich fashion, and I wanted to place one more above the switch plate to frame up the key banks and make the end result look less raw and industrial.

Many US-based keyboard builders use Ponoko for acrylic components, but their shipping to Japan was expensive and I hoped to avoid them. If not for COVID-19, I might have visited some of the Tokyo-based operations in person, but their online ordering interfaces did not have the flexibility I needed. Ponoko also had a black glitter acrylic that I really wanted to use. I decided to postpone the decision on acrylic while I focused on getting the electrics working and building the bare minimum structure necessary to use it.

Controller

I had bought a Teensy++ 2.0 back in the winter of 2018, intending to do something along the lines of what I was now preparing to do, but it didn't happen and the board was still sitting idle, so I conveniently did not need to buy anything to use for a controller.

USB Port

I wanted a fixed USB port mounted on the back of the keyboard for a modular cable, but trying to mount the controller board flush with the edge of the case was not a good proposition. Any way I could think to do it would make the keyboard too thick, and require clearance in the opening for wires coming into through holes near the USB port.

To work around this, I ordered a Polulu USB Type C breakout board, which I could secure to the underlying acrylic sheet with nuts and screws, and which could have all of its wires connected in the rear.

Wiring

I ordered spools of wire from AdaFruit and a ribbon cable with clamp to connect the controller to the matrix, and diodes, from DigiKey.